Jasper Plastics' overarching commitment to quality and customer service is shown in every part that we manufacture and every business relationship we have established in the almost 20 years that we have been in business.

JASPER PLASTICS:

‘ja-sper |\ plas tic

1. A manufacturer of plastic, polyurethane, and fiberglass parts for OEM manufacturers in the construction, lifestyle, and Recreational Vehicle sectors.

2. One of the USA’s leading manufacturers of molded polyurethane products.

3. A company that believes in treating the customer as they want to be treated-where customer service and quality come first..

4. We pride ourselves in not offering the same products that everyone else is. We work with you to create a custom look that will be unique to your company's individual needs and goals

POLYURETHANE MANUFACTURING

Jasper Plastics is one of the larger manufacturers of molded polyurethane parts in the country.

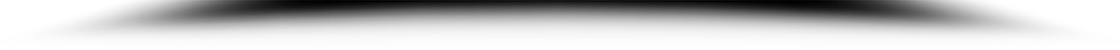

Jasper Plastics is a leader in providing molded polyurethane parts as an alternative to traditionally manufactured wood, stone, and tile. The Advantage of Jasper Plastics manufactured polyurethane parts is threefold:

-

Consistency:

Because our parts are created from a mold, each part we supply is identical to the rest.

-

Cost:

Because our parts are not made from limited resources and natural materials, we can supply you more economically.

-

Weight:

Polyurethane is a fraction of the weight when used to replace wood or stone products, yet will mimic the same texture and appearance.

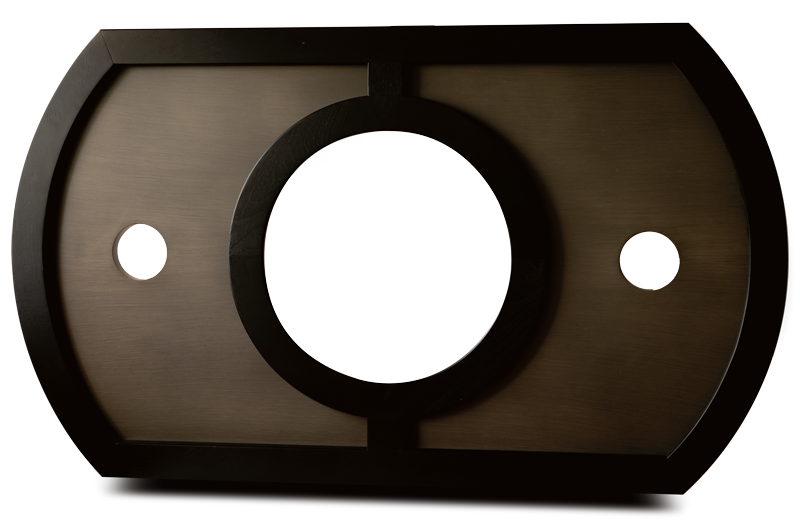

IN THIS VIDEO…our customer wanted a fireplace insert that had raised stone of various heights on the front. Our artists created a design that the customer liked, and they told us to move forward. Because 3D printing is very time-consuming, it can be expensive, but since that Jasper has the ability to manufacture in several different types of materials, we utilized our Wide Format HD 3D printer to make a pattern and then created a silicon mold. Copies of that mold are seen in this video. Using our HD 3D printer to prototype the part we saved considerable time for the customer. By utilizing polyurethane molding technology and then printing the design on the blanks, we save production time which translates into monetary savings for our customers.

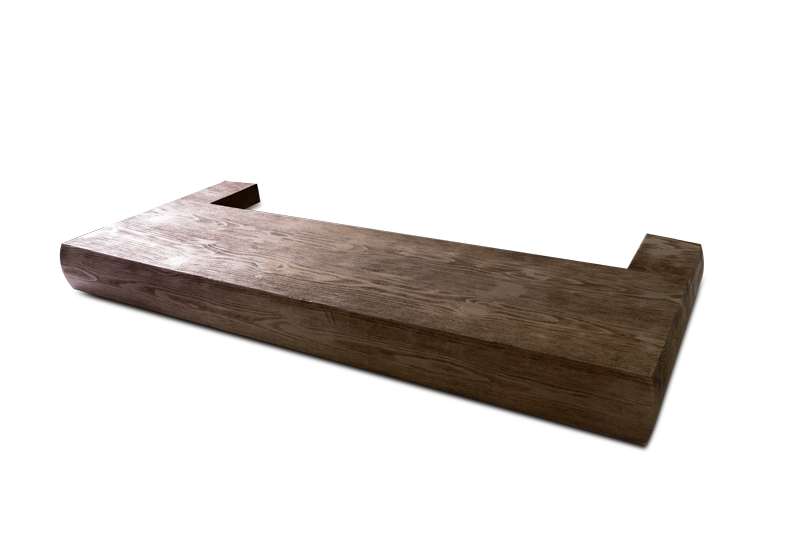

Why we need to make a mold

A mold is what we use to form our polyurethane and fiberglass products. We use these molds in order to provide a uniform manufactured part to your exact specifications. Molds ensure that you will get the correct size, texture, and look each time that product is made with very little if any deviation.

Molded polyurethane has outstanding durability as it is more durable than most other plastics and rubber. It is extremely resistant to heat and water, and unlike wood or laminates, will not absorb water or rot.

With a library of over 6000 SKUs of molded parts, you can bet we know a thing or two about molding polyurethane. Our staff engineers and chemists keep us dialed in and consistent so that we can deliver invariable parts to our customers every day of the week. In the video, you will see our team members pouring, demolding, prepping, and finally finishing a polyurethane fireplace insert.

WHY POLYURETHANE PRODUCTS? PERHAPS A BETTER QUESTION IS “WHY NOT?”

Polyurethane is waterproof, durable, heat-resistant, and proven to withstand both indoor and outdoor temps without the fear of dry rot, decay, or water absorption. Polyurethane parts allow for quick, consistent, and easy installation.

WALL COVERINGS

TEXTURE

ASSEMBLY

CONSISTENT SIZE AND FINISH

To Find Out How Jasper Plastics Can Help You, Contact Our Corporate Office:

Jasper Plastics

office: 574.457.2062

fax:574.457.2069

contact@jasperplasticssolutions.com

501 West Railroad Ave

Syracuse, IN 46567

Our sister company,

Leading Edge Countertops

office:574.658.3291

customerservice@leadingedgecountertops.com

501 West Railroad Ave

Suite A

Syracuse, IN 46567